Choosing the right actuator—electric or hydraulic—is critical for the success of any mechanical system, whether it’s in manufacturing, aerospace, automotive, or robotics. This decision impacts not only the efficiency and functionality of the operation but also its maintenance, cost, and adaptability to future technologies. This article provides an in-depth look at both electric and hydraulic actuators, helping you determine the best fit based on your specific application needs.

Understanding the Basics:

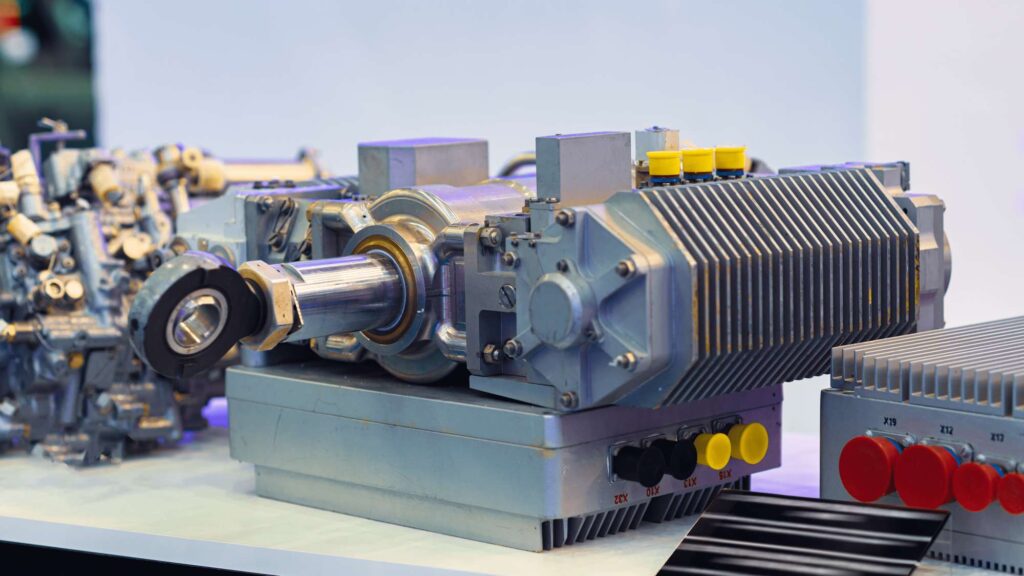

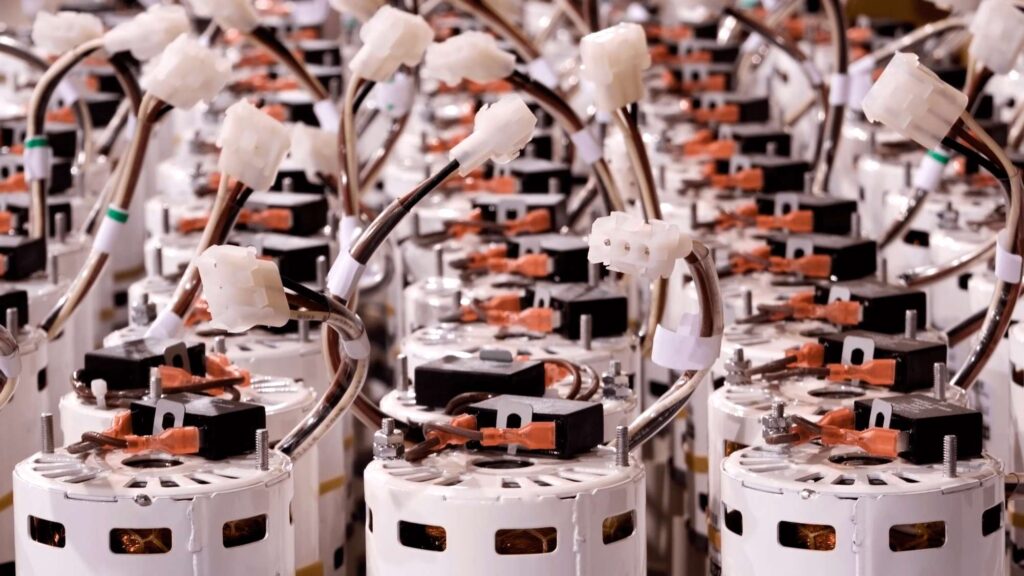

Electric actuators utilize an electric motor to convert electrical energy into mechanical torque. These actuators are known for their precision, speed control, and ability to integrate with digital control systems. They are widely used in environments where accuracy, cleanliness, and low noise are required.

Hydraulic actuators operate by using fluid pressure to generate force and motion. Hydraulic actuators are renowned for their high power density and ability to exert large forces, making them suitable for heavy-duty applications such as construction and mining.

Performance and Suitability:

Efficiency and Control:

Electric actuators offer high efficiency as they directly convert electrical energy into mechanical motion. They provide excellent control with the ability to adjust speed, position, and torque seamlessly, which is crucial for precision applications.

Hydraulic actuators, while not as efficient due to energy losses in fluid compression and flow, they excel in applications requiring large force outputs and can be more cost-effective in such scenarios.

Load and Speed Capabilities:

Electric actuators are best suited for applications requiring moderate to high speed and precise load handling. Ideal for automated manufacturing, medical devices, and consumer electronics.

Hydraulic actuators are the go-to choice for extremely high-load applications where speed is less critical than the sheer ability to move heavy objects, such as in earthmoving equipment or industrial presses.

Installation and Maintenance:

Electric actuators are generally easier and cheaper to install and maintain due to fewer moving parts and no need for a fluid reservoir or piping. The lack of fluids also eliminates the risk of leaks and environmental contamination.

Hydraulic actuators require more complex installation with a system of pumps and fluid reservoirs. Maintenance needs are higher due to potential fluid leaks and the need to monitor fluid quality and levels.

Cost Considerations:

Electric actuators often carry a higher upfront cost due to their sophisticated control systems and components. However, the total cost of ownership can be lower over time due to lower maintenance costs.

Hydraulic systems may have lower initial costs but can be more expensive in the long run due to maintenance, repairs, and energy inefficiency.

Environmental and Regulatory Factors:

Electric actuators align better with environmental regulations and sustainability goals. They produce no emissions directly and can be powered by renewable energy sources.

Hydraulic actuators can pose environmental risks due to potential fluid leaks. However, advances in biodegradable hydraulic fluids are mitigating these impacts.

The choice between electric and hydraulic actuators depends heavily on the specific demands of your application. Consider factors like required force, precision, speed, environmental considerations, and total cost of ownership. Electric actuators are generally preferred for precision and clean environments, while hydraulic actuators are favored in settings where high force and robustness are paramount. Before making a decision, evaluate the long-term implications of each type on your operation’s efficiency, sustainability, and compliance with industry standards.