In the realm of electric motors used across industries from robotics to aerospace, the brushless DC (BLDC) motor stands out for its efficiency and performance. Among the various innovations in motor technology, the slotless BLDC motor offers distinct advantages over traditional slotted designs. Unlike conventional motors where copper windings are inserted into the iron slots of the stator, slotless BLDC motors feature a unique design where the windings are arranged in a smooth cylindrical shape.

This fundamental change not only affects the motor’s electromagnetic interactions but also enhances its operational characteristics significantly. This article delves into the mechanics of slotless BLDC motors, exploring how their innovative design leads to improved performance and reliability, and why they are increasingly preferred in applications where precision and efficiency are critical.

Design and Operation:

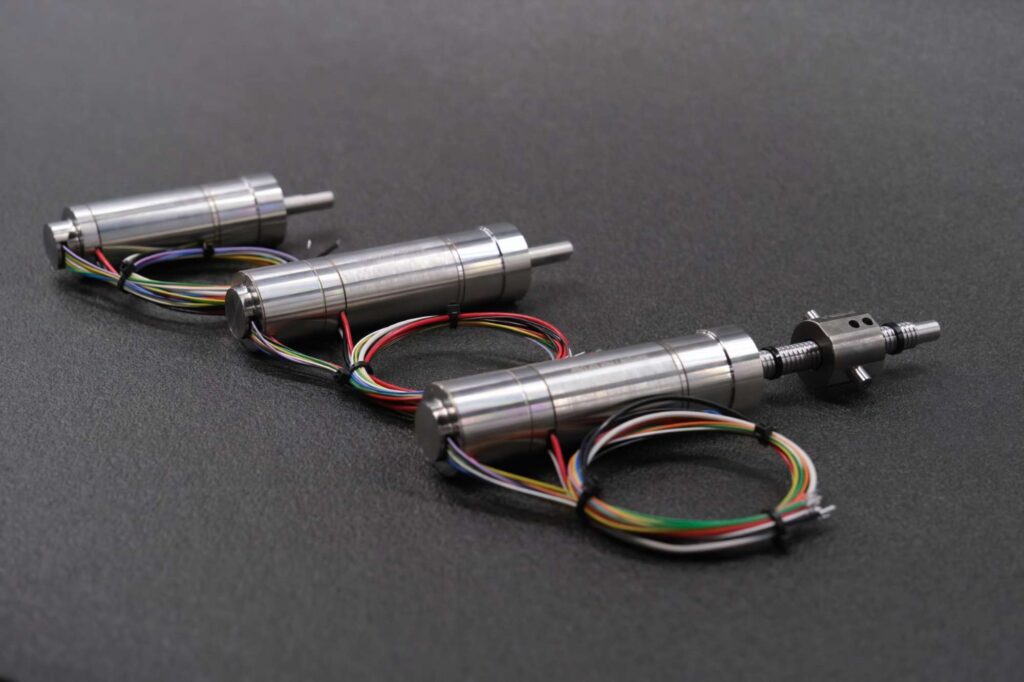

Slotless BLDC motors are engineered without the iron-core slots typically found in the stators of traditional motors. This design eliminates the cogging torque—unwanted torque ripples caused by the interaction between the magnets of the rotor and the iron teeth of the stator. The windings in a slotless BLDC motor are embedded in a laminated core that forms a smooth cylindrical inner stator surface, which results in several performance enhancements.

The lack of slots significantly reduces magnetic cogging, enabling smoother and more uniform rotation. This is particularly advantageous in applications requiring high precision and low-speed control.

Performance Advantages:

Slotless BLDC motors offer superior performance characteristics compared to their slotted counterparts:

- Reduced Cogging Torque: The smooth operation is ideal for applications like medical devices or precision optical instruments where stability and noise reduction are paramount.

- Higher Speed Capabilities: Without the inductive resistance imposed by stator teeth, slotless motors can achieve higher speeds with reduced electromagnetic interference, making them suitable for high-speed applications.

- Enhanced Thermal Efficiency: The unique winding arrangement allows for better heat dissipation, which is critical in maintaining performance and extending the motor’s lifespan under continuous operation.

Applications:

The benefits of slotless BLDC motors make them particularly effective in several demanding fields:

- Aerospace and Defense: Employed in critical systems where reliability and performance are crucial under varying operational conditions.

- Consumer Electronics: Integral to enhancing the user experience in devices such as drones and high-performance portable tools by providing efficient, reliable motion control.

- Medical Devices: Used in surgical tools and imaging equipment where precision and minimal acoustic noise are required.

The slotless BLDC motor is a remarkable example of how advancements in motor design can lead to significant improvements in performance and application suitability. By understanding the benefits and operational efficiencies of slotless motor technology, engineers and designers can better tailor their product selections to meet the demanding requirements of modern applications. For industries pushing the boundaries of precision and efficiency, slotless BLDC motors represent a key technological advantage.